PNEUMATIC AIR COMPONENTS INFO.

Pneumatic air control systems have been around in model railroading for over 50 years. Three former manufacturers---Del-Aire, EZ-Aire, and Sunset Valley --- are all now out of production, but I still have many pneumatic air components available.

Air motors (also called pneumatic motors) are about the same price as electromagnetic switch machines, but offer far superior performance (not to mention that they don't dim the lights on the rest of your layout while being energized).

Here's why they perform better. Air-motors are continuously applying a force to the points — either by the air pressure pushing one way, or by a spring pulling the opposite way. Therefore, the points are held against the rails at all times regardless which way the switch is thrown. Using air motors, you will never have a derailment caused by wheels having to "pick" which side of the points they will go.

Another advantage is that pneumatic motors typically use a toggle switch, not a push button, so the direction of the toggle can also serve as an indicator of the position the turnout is in.

Using air-operated switch machines requires an air source, but you don't have to buy an expensive air compressor. All you need is a portable air tank of some sort. This could be something as robust as a compressed air tank sold at Wal-mart, etc., or as simple as an empty 2-liter soda container. An inner tube even works just fine as an air reservoir and will last for weeks between refills. When you need to refill your air "tank," just take it to the neighborhood gas station and pump it back up again. A pressure of about 40 psi is all you need.

Not convinced yet? There are still several additional advantages of air-operated switch machines over electromagnetic ones that I haven't covered yet.

- First, there are no coils to burnout. You can expect air motors to last your lifetime... and then some!

- Second, with traditional switch machines, it's a time consuming art to get adjustments just right so that the points are against the rails either way the switch is thrown. That's because the range of the throw in a traditional switch machine throw was just about the same distance as the movement of the points. Once you have it right on one side, throwing the switch the other direction would not put the points against the rails. With air-operated motors, the throw range is about 2 to 3 times the range that the points move. Most of the time after installing the air-motor, you don't have to make any adjustments at all.

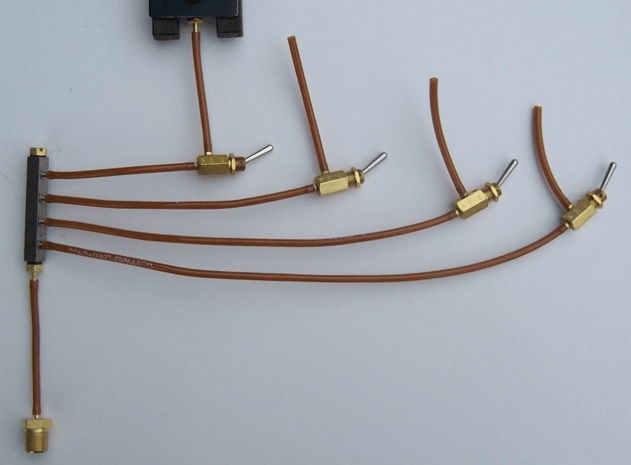

- Third, ease of installation. With air motors, only 1/16" plastic tubing is used to route power. As a result, you have no maze of electrical wire running under your train table. Using a manifold, you can even control multiple turnouts from a single toggle ! Manifolds are available with 4, 6, 8, or 12 outlets.

- Fourth, air motors can be used for much more than switch machines. For example, you can use an air motor to pull down a gate to allow pipes to roll onto your flatbed. The possibilities are endless.

We use it on our club layout to operate a rotary coal dump !

- Fifth, durability. The pneumatic motors have only one moving part internally. These pneumatic motors can even be used outdoors.

- Finally, convenience. These motors easily mount to your table. Connecting the air supply is just a matter of pushing the tube onto the barb... no tools necessary. Moreover, the length of the throw and the flexibility of the throw rod is much more forgiving than other types of switch machines. Mounting these pneumatic motors under the table is quicker and easier than mounting conventional switch machines on top of the table! Adjustments are often not necessary with the air motors.

So what, then, are the disadvantages of using air-powered switch machines? The only disadvantage we can think of is that compressed air is less convenient to acquire than electricity. For electric switch machines, powering it is just a matter of plugging in the transformer. For air motors, powering it might mean having to take an inner tube to the gas station, inflate it with a bicycle tire pump a few times a year….. or refill your air tank from a compressor periodically.

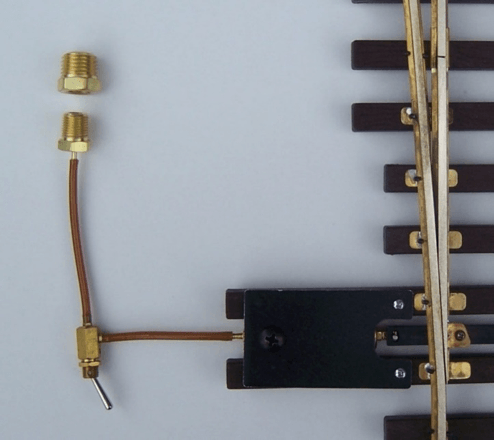

Installation is very simple. All you need is an actuator, a toggle switch, some hose, and a compressed air supply (The hose can be up to 200 ft. long). The toggle switch either applies or releases air pressure to the actuator, which throws the turnout. An internal stainless steel spring in the actuator resets the turnout when pressure is released.

Usually you will want to control several turnouts; this is achieved by the use of a manifold as shown. Connecting a hose is easy, just push it over the barbed fitting for a permanent join. The user needs to provide a small compressor to supply air at 30psi to the system, which are inexpensive and available from Harbor Freight and other supply companies.

PNEUMATIC AIR COMPONENTS

Shown below are the primary components of the pneumatic air systems. They may look slightly different from one manufacturer to another, but they are all compatible. Since these components are not currently in production, I may or may not have all components in stock. That should be indicated in the Products listings.

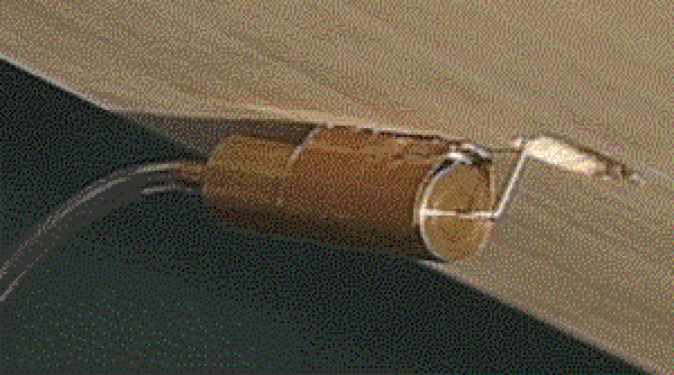

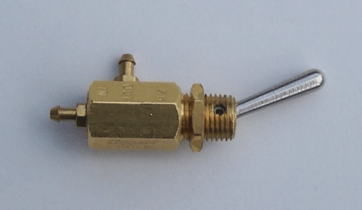

The actuator is screwed to the headblocks of the turnout and the throw pin is inserted into a hole drilled in the throwbar. Up to 1/2” movement is possible, most turnouts need about 1/4". A right angle elbow (ELL) can be fitted so the hose enters from the bottom or side.

The toggle switch is mounted on a panel for convenience. Connect the back port to the supply and the side port to the turnout.

The hose is UV resistant polyurethane. Simply push onto the barbed fittings of components for a permanent connection.

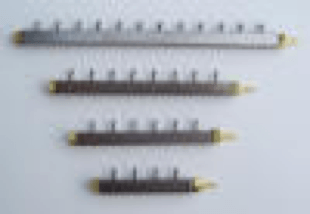

Manifolds are used for controlling multiple switches. Four sizes are available, with 4, 6, 8 or 12 outlets. Connect unused pairs of parts on the manifold with short pieces of hose.

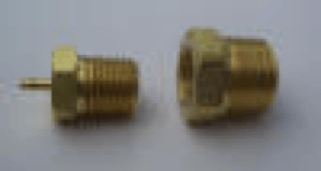

Adaptor set to connect the system to an air compressor. Adaptor has a 1/8”NPT and a 1/4" NPT male fitting (2 pcs).

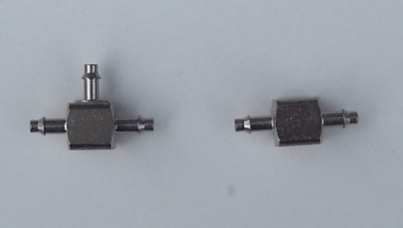

Use a tee to operate two turnouts simultaneously from one toggle switch. Use a union to join two pieces of hose.

Use a Quick Disconnect when you need to frequently break a line, for example across a lift bridge etc. Press the end cap to release the tube.

Use an Indicator, to tell if the line to each switch is activated. Just tee off the line to the switch. Red and green available.